Quality

Quality Assurance and Inspection Technology

HB Bearings are at the forefront of inspection technology. During manufacture, bearings are subject to a rigorous inspection program which takes place before final assembly. HB Bearings have two temperature controlled inspection rooms with state-of-the-art computerised (CNC) inspection equipment. This ranges from hardness testing, surface finish, roundness testing, contour inspection and co-ordinate measuring machines. We are in a position to provide precision bearings and be confident of the quality via stringent inspection regimes.

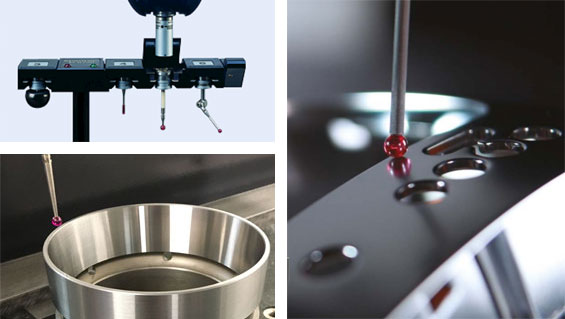

CNC MEASURING MACHINES

A recent addition to our Inspection room, the Mitutoyo CMM Crysta-Apex-S.

A bearing about to be measured (left) on the Mitutoyo Strato CNC measuring machine in one of our temperature controlled inspection rooms, part of the inspection process.

CONTOUR TRACING MACHINE

This allows checking of the radii of ball tracks and their position in the bearing as well as many other dimensions. Close up of contour tracing a bearing track (right)

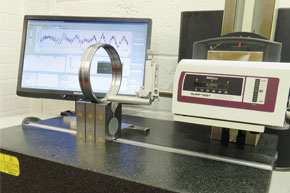

SURFACE FINISH TESTING MACHINE

The surface finish testing machine (above), allows checking of the surface finish, even across a ball track radius

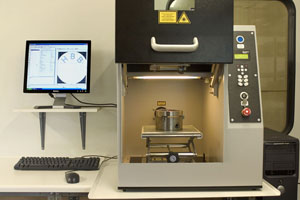

LASER ETCHING MACHINE

Laser etching machine. Used to accurately mark bearings with reference numbers and additional information if required.